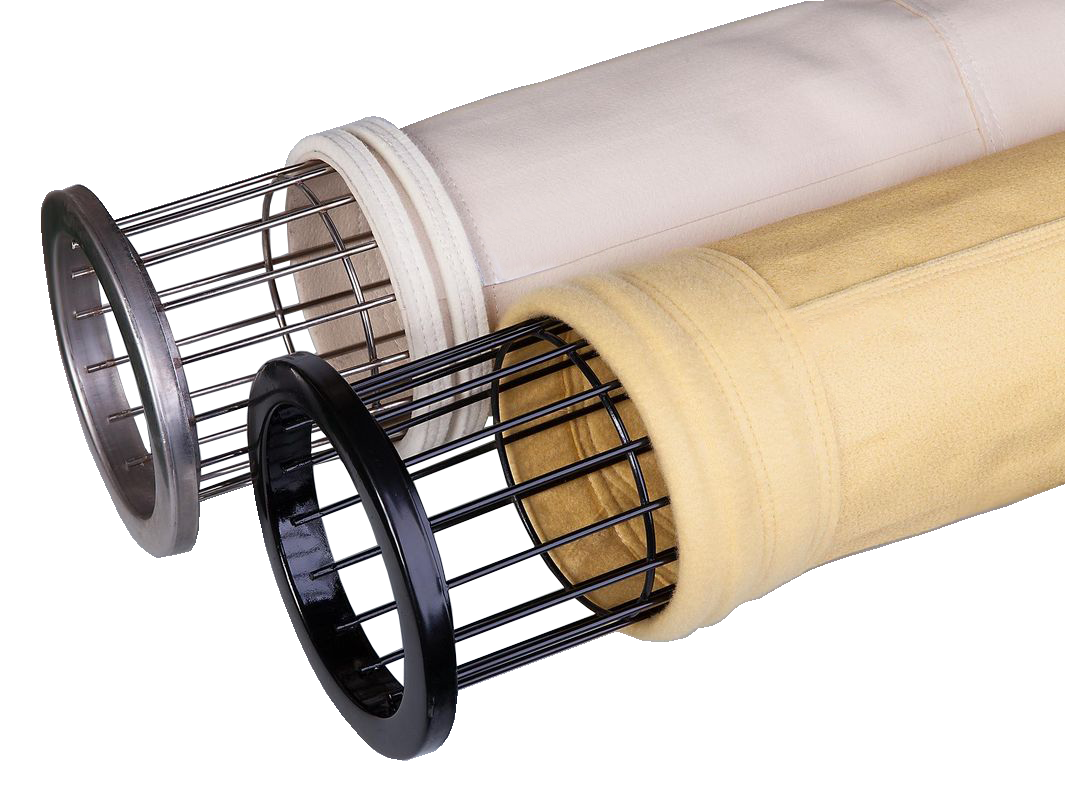

FILTER BAGS

A clean environment is the right of all people. The important thing is not to clean the environment, but to keep it clean.

Our Principles:

✓ Improve quality of life.

✓ Get the quality air you want.

✓ To destroy harmful viruses and bacteria.

IMPORTANCE OF FILTERS

Filters should be used to improve the quality of life and to obtain quality air in various industries, to reduce harmful viruses and bacteria. It is very important to change the filter bags used in the ventilation installations for a certain period of time.

TYPES of FILTERS

✓ Polypropylene

Heat resistant up to 90-100° C.

These Filter bags consist of 100% pure polypropylene microfibers. Extremely high quality fiber structure creates high filtration efficiency and large contact field. Polypropylene has hydrophobic and oleophilic properties of water to attract oils, and filter bags to dissolve water make it possible to separate and remove oils. Polypropylene bags are suitable for fine chemicals, food, beverages and medicine.

✓ Polyester

Heat resistant up to 135-150° C.

Polyester filter bags provide reliable, durable performance and are more resistant to heavy loads than filter bags made of other materials. Polyester filter bags are used in various industries including food processing, chemical processing, general industrial processing and manufacturing. These filter bags are known for their high quality, reliability and durability in industrial environments.

✓ Meta-Aramid

Heat resistant up to 200-220° C.

Meta-Aramid filter bag is also called Nomex filter bag. Bu filterlər yüksək intensivliyi, yaxşı sürtünmə və qatlama müqavimətinə mənsubdur. Without major changes to dust collectors system filtration capacity can be increased by 50-150%. One of the main features is that it is resistant to high temperatures.

✓ Nylon

Heat resistant up to 135-145° C.

Nylon monofilament (NMU) filter bags are made of special material. Nylon threads touch accurately and heat-stabilize with stable, consistent openings. It has high filtration performance. Supported side seams prevent fluid from moving to the edge. An effective filter system for removing coarse particles.

✓ Teflon

Teflon is made using 100% synthetic fiber. It has the ability to remove both solid and salty particles and to hold high dirt. Available in all industry standards compliance and custom sizes. Has a wide range of chemical compatibility. It creates a low pressure area because it has a high flow rate.

AREAS OF USE

Cement Plant

Concrete Plant

Asphalt Plant

Tobacco Plant

Food Industry

Mining Facilities

Fertilizer Industry

Chemical Industry

Glass Production

Casting Industry

Aluminum Industry

Lime-gypsum Plant

Plastic Industry

Furniture and paper industry